KT纖維水泥板

CUBM has developed a high-performance fiber cement board that can also cope with water attack: KINGTEC KT panel

Features

Exceptional Quality

Sound insulation

Waterproof and moisture-proof

Fire resistant

Energy saving

Easy to install

Anti-mildew and antibacterial

The Problem

-

High stress of buildings and their walls, causedth rough high traffic special load (e.g. hospitals)a ndv andaislm (e.g. Schools)

-

High renovation requirement in public buildings

-

Security, robustness, longevity and quality needs

-

• Special demandosn soundprotection and fire protection

Test Repoet

The solution: KINGTEC KT Panel

-

Composed of inorganic raw material such as cement, silica and cellulose fibre

-

High scratch resistance, impact resistance Smooth surface

-

Autoclaved to create stable properties Simple joint treatment for tapered board edge

-

High bending strength, low water absorption rate

Test Report Certificate

KINGTEC KT Panel is the idea board for water resistance, impact-resistance, abuse resistance in public buildings such as school or hospitals, where robustness, longevity and quality are particularly important. It is well qualified for internal and external environment.。

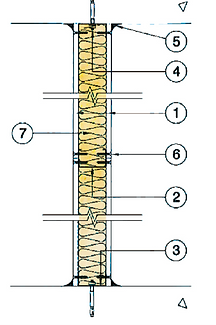

KINGTEC FIRE / IMPACT RESISTANT FIBRE CEMENT BOARD PARTITION SYSTEM

-

KINGTEC KT Panel fibre cement board, 9mm thick

-

50mm x 0.5mm Forta G.I. Stud at 610mm centres

-

50mm x 0.5mm Forta G.I.' U' channel

-

Nai/able plug at 600mm centres

-

Fire resistant mastic

-

Dywall screw at 250mm centres 7.50mm thick, 80kg/m3, BNS rockwool

Technical Data:

1-Hour fire rating, integrity & insulation Accord ing to BS 476: Part22, BS476: Part20 with fire risk from both sides Overall partition thickness = 68mm (when 75mm wide stud is used, with 50mm thick 100kg/m3 BNS rockwool)

KINGTEC KT PANEL WET AREA APPLICATION

The main function of constructions in damp and humid areas is to prevent water or moisture penetration into internal walls, floors and ceilings. Damp or humid areas shouldm always be built from materia that can withstand moisture and water. KINGTEC KT Panel composed of fibre cement is processed by high pressure. It is stable and water resistant, and has been developed f or demanding applications such as the following:

Wall Liner should be specified:

-

Where a variable stand-off clearance is required between lining and background

-

Where background is poor or damp.

-

Where insulation is required within the wall lining void.

-

Where deep service runs are required to be accommodated within the lining void.

This system utilizes metal channel and bracket components to form a rigid framework for cement board. Technical recommendation shall be seeked from manufacturer for nonstandard situation. 'U' Mounting Brackets prov ide a variable stand-off from the background. The lining void facilitates the introduction of thermal or sound insulation and provides containment for service runs. 'C' Channel forms the main wall lining stud which has extra wide flanges promoting strength and greater sealing for vapour resistance and board attachment. The system is capable of overriding substantial irregularities in the background.

KINGTEC KT PANEL WALL LINING SYSTEM

KINGTEC KT Panel can combine with different kinds of channel to form ceilings / bulkheads. These ceilings are simple to install. They are designed for various decoration effect and harsh environments such as high temperature, high humidity

C-Form Channel Ceiling

This ceiling system can be designed to various 3-D modeling with gradual pattern effects. It is popular for large sized ceiling over 50m2and spans in excess of 4m and for deeper ceiling void over 450mm. C-shaped Channel ceiling should be considered when the imposed load is 80-100kg. Where strict deflection is required, the cei ling frame arrangement shall be checked by qualified structural engineer.

Lightweight Ceiling

This ceiling system is designed for simplicity and minimum ceiling void. It is suitable for small ceiling less than 50m2 and spans less than 4m.

Fixing and fastenings

KINGTEC KT Panel shall be fixed to steel or timber studs by countersunk cutting head screw. Because of its strength it is easy to attach different hangers to KINGTEC KT Panel. Fastenings for heavy attachments should be centered on internal studwork.

Decoration

Painting & Papering:

Any conventional paints can be used. Alkali resistant primers are not necessary. Water based paints (with a watered down first coat) or oil-based paints can be applied to all products using proprietary primer/ top coat systems as recommended by paint manufacturers. When papering KINGTEC KT Panel, size to seal against suction and improve slip, then hang papers or vinyl in the normal way.

Plastering:

If a skim finish is desired, fix textured side out, apply a sealing coat of universal primer and allow to dry. Follow with a second coat. Apply plaster while this coat is wet and tacky. All times strictly follow plaster/joint-ing compound manufacturer’s instructions for applying to fibre cement boards.

Tiling:

Minimum 9mm thick boards should be used. Supports should be maximum 400mm centres with cross noggins at transverse board joints. Seal the boards with RVA Countersunk corrosion resistant screws should be used to fix boards at 200mm centres. Fix tiles in strict accor dance with manufacturer’s recommenda-tions.

Seamless jointing

1. Basic knowledge

Sound is the vibration of an object that is felt through the human auditory organ. Acoustics involves many disciplines such as natural science, psychology, and art. The normal hearing frequency range of the human ear is 20 - 20KHz, 5OOHz and below is low frequency, 500Hz - 2000Hz is medium frequency, and 2000Hz is high frequency. The sound level is used to describe the size of the sound, which is calculated by adding the sound of each frequency. Generally, the A sound level is used. The hearing sound level range of the human ear is 0-120dB. Below 15dB is an extremely quiet environment, 25-30dB is a quiet environment, 30-35dB is a quiet environment, and above 40-50dB is a noisy environment. Noise damages hearing, affects health, and interferes with work and normal life, so it should be controlled. The sound insulation of a wall is an indicator of the wall's ability to isolate noise. The larger the value, the better the sound insulation effect.

2. Principle of air sound insulation

Drywall adopts double-layer wall or multi-layer composite structure, leaving a certain air gap between the wall surfaces. Due to the elastic layer effect of the air layer, the sound insulation of the total wall can exceed the mass law and meet the requirements of the design specifications. Placing sound-absorbing materials in the air layer of the drywall will further improve the sound insulation of the drywall. Rock wool and glass wool have good sound absorption performance and can be used as filling materials in soundproof drywall. The flexible sealing connection structure of the drywall not only ensures the elastic layer effect of the air layer, but also effectively avoids the existence of sound bridges (sound bridges cause sound reduction). The drywall uses two boards of different thicknesses or densities to prevent the two boards from matching at the same time. The matching valleys of the two panels are staggered, thereby improving the sound insulation performance of the wall.

3. Inspection standards

The air sound insulation of KT partition walls complies with the "Building Sound Insulation Evaluation Standard" (GB/T19889.3-2005) KT partition wall air sound insulation testing complies with the "Sound Insulation Measurement of Acoustic Buildings and Building Components" (GB/T19889.3-2005)

3. Inspection standards

|  |

|---|